SEO Title with Number Included

Introduction: Why Lightweight Chassis Matter in Motorsport

In the high-speed world of motorsport, every gram matters. Whether competing in Formula 1, NASCAR Cup Series, or the legendary 24 Hours of Le Mans, engineers obsess over one core principle: reduce weight without sacrificing strength.

The racing chassis — the structural backbone of a race car — determines handling, acceleration, safety, and aerodynamic performance. A lightweight chassis improves:

- Power-to-weight ratio Lightweight Racing Chassis

- Cornering agility Lightweight Racing Chassis

- Braking efficiency Lightweight Racing Chassis

- Tire wear management

- Fuel efficiency Lightweight Racing Chassis

- Overall race pace

This in-depth guide explores the science, materials, technologies, and engineering innovations behind lightweight racing chassis systems used in modern motorsport.

1. What Is a Lightweight Racing Chassis?

Definition and Core Function Lightweight Racing Chassis

A racing chassis is the structural framework that supports the suspension, engine, transmission, aerodynamic components, and driver safety cell. In high-performance racing cars, the chassis must:

- Be extremely rigid

- Absorb crash energy

- Maintain dimensional stability

- Minimize weight

Unlike road cars, racing chassis are purpose-built for maximum performance under extreme loads.

2. The Evolution of Racing Chassis Design

Early Ladder Frames Lightweight Racing Chassis

Early race cars used simple steel ladder frames. While durable, they were heavy and lacked torsional rigidity.

Tubular Space Frames Lightweight Racing Chassis

Space frame designs improved stiffness while reducing weight. Popular in GT and endurance racing.

Aluminum Monocoque Revolution

The major shift came with aluminum monocoque structures — pioneered in Formula 1 in the 1960s.

Carbon Fiber Monocoque Era

Today, nearly all top-tier motorsport series use carbon fiber composite monocoques for unmatched strength-to-weight ratio.

3. Materials Used in Lightweight Racing Chassis

3.1 Carbon Fiber Composites

Carbon fiber is the gold standard in modern motorsport.

Advantages:

- Extremely light

- High tensile strength

- Excellent stiffness

- Superior crash energy absorption

Used extensively in:

- Formula 1

- IndyCar Series

- FIA World Endurance Championship

3.2 Aluminum Alloys

Still used in lower-tier racing due to cost-effectiveness and good strength.

3.3 Titanium Components

Used for:

- Mounting brackets

- Reinforcement areas

- High-stress suspension pickup points

3.4 Magnesium Alloys

Ultra-light but expensive and flammable — used selectively.

4. Monocoque vs Space Frame Chassis

| Feature | Monocoque | Space Frame |

|---|---|---|

| Weight | Extremely light | Moderate |

| Rigidity | Very high | Medium |

| Cost | Expensive | Affordable |

| Common In | F1, IndyCar | GT racing |

5. The Science of Torsional Rigidity

Torsional rigidity measures resistance to twisting forces. High rigidity ensures:

- Precise suspension geometry

- Improved cornering stability

- Predictable handling

In modern Formula 1 cars, torsional rigidity can exceed 30,000 Nm/degree.

6. Aerodynamics and Chassis Integration

The chassis integrates with aerodynamic elements like:

- Diffusers

- Sidepods

- Underbody tunnels

- Front and rear wings

In FIA World Endurance Championship cars, chassis design works with ground effect principles to maximize downforce.

7. Safety Engineering in Lightweight Chassis

Modern racing chassis are built around a survival cell.

Key Safety Features:

- Carbon fiber crash structures

- Side-impact panels

- Energy-absorbing nose cones

- Fire-resistant materials

Following incidents in Formula 1, FIA regulations now require advanced impact tests before homologation.

8. Weight Distribution & Center of Gravity

Lightweight chassis design enables:

- Lower center of gravity

- Optimal front-rear balance

- Reduced polar moment of inertia

Critical for:

- High-speed cornering

- Quick direction changes

- Stability under braking

9. Manufacturing Techniques

Autoclave Curing

Carbon fiber layers are baked under pressure for maximum strength.

Prepreg Layup

Pre-impregnated carbon sheets allow precise fiber orientation.

CAD & Simulation

Teams use advanced modeling software to optimize:

- Load paths

- Impact resistance

- Structural stress distribution

10. Lightweight Chassis in Endurance Racing

Endurance events like the 24 Hours of Le Mans require:

- Durability over 24 hours

- Impact resistance

- Repairability

Chassis must balance lightness with longevity.

11. Electric & Hybrid Racing Chassis

Electric racing series like Formula E present new challenges:

- Heavy battery packs

- Thermal management

- Structural reinforcement

Lightweight chassis designs compensate for battery mass.

12. Cost vs Performance Trade-Off

Carbon fiber chassis can cost millions to develop.

Lower-tier racing often uses:

- Steel tube frames

- Aluminum monocoques

- Hybrid composite solutions

13. Future Innovations in Lightweight Chassis

Emerging trends include:

- Graphene composites

- 3D printed titanium joints

- Sustainable carbon fiber

- AI-driven structural optimization

Motorsport innovation often transfers to road cars, including brands like Ferrari and McLaren Automotive.

14. Internal Links (For Your Website Structure)

You can link this article internally to:

- /race-car-aerodynamics

- /carbon-fiber-race-cars

- /motorsport-safety-technology

- /race-car-suspension-setup

- /high-speed-drag-reduction

15. External Authority Links (For SEO Boost)

For credibility, link externally to:

- FIA Technical Regulations

- Official Fédération Internationale de l’Automobile website

- Formula 1 Technical Insights

- Engineering resources from SAE International

Images for Your Website (Suggested Placement)

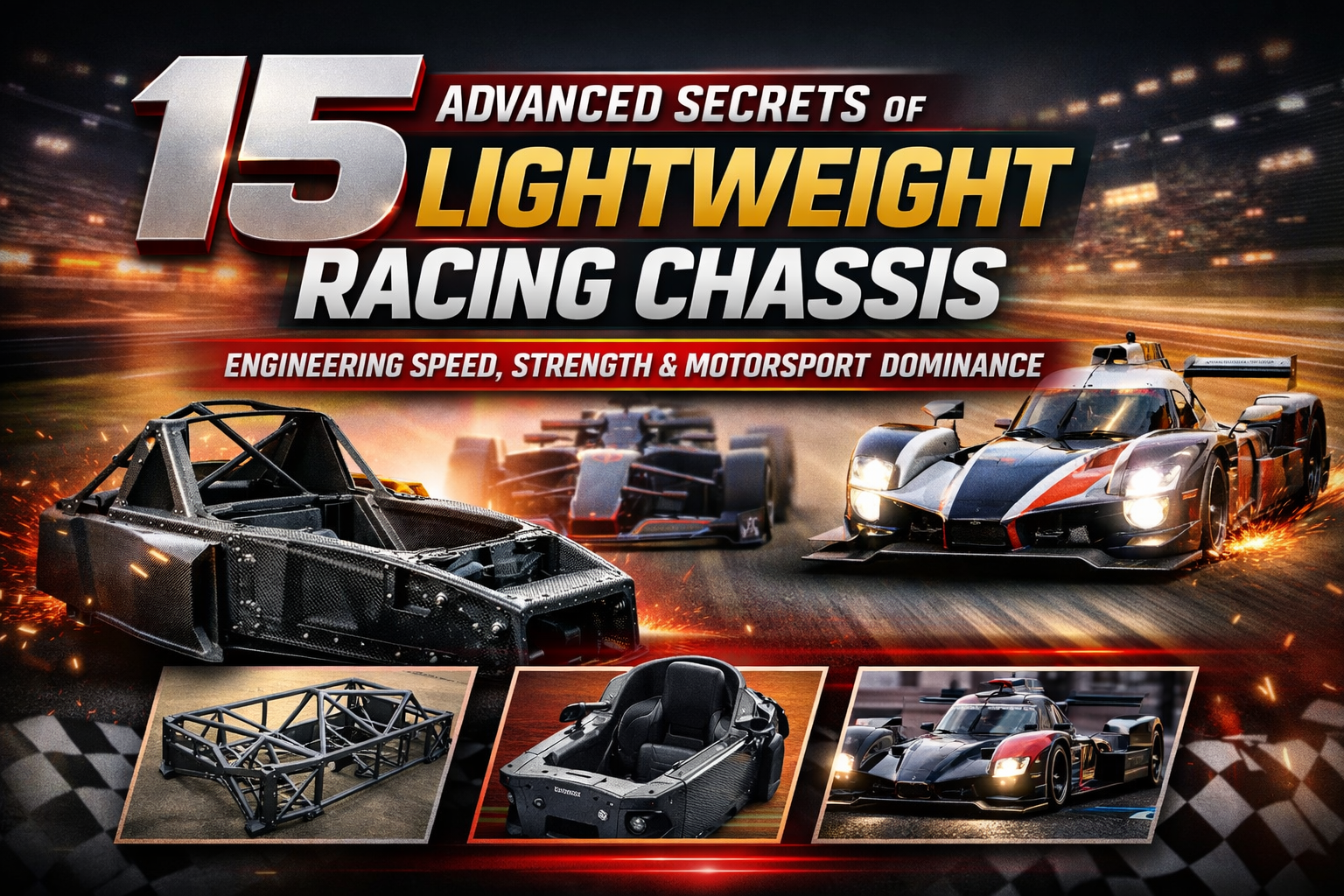

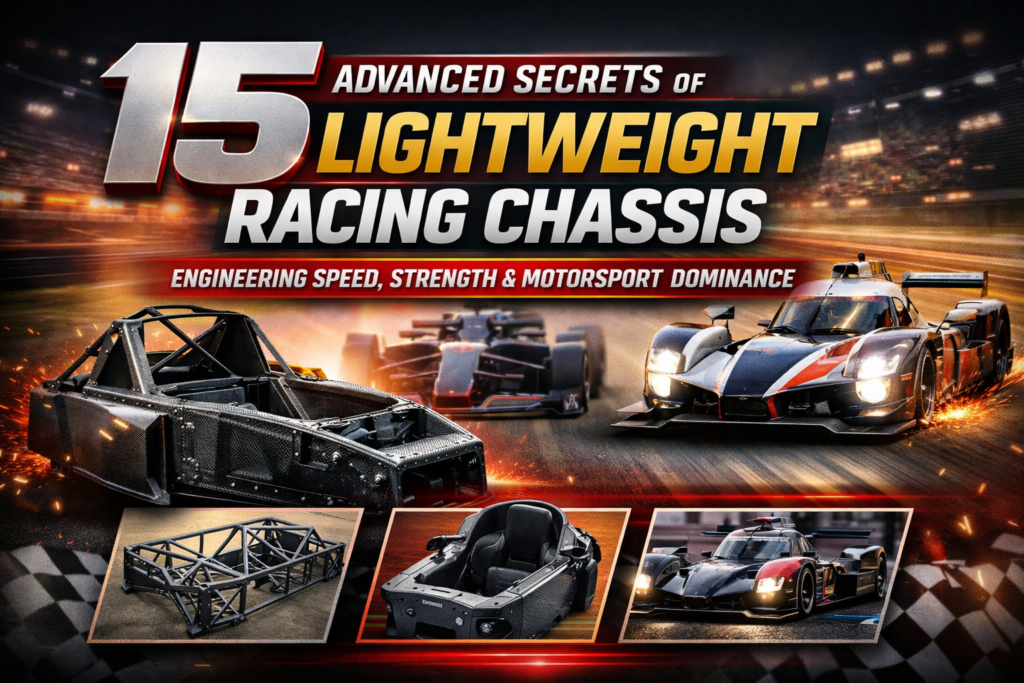

🖼 Image 1: Carbon Fiber Monocoque Structure

Alt text: Lightweight carbon fiber racing chassis structure

Placement: After Section 3

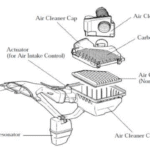

🖼 Image 2: Space Frame Racing Chassis

Alt text: Tubular space frame race car chassis

Placement: After Section 4

🖼 Image 3: F1 Carbon Survival Cell

Alt text: Formula 1 carbon fiber monocoque safety cell

Placement: Section 7

🖼 Image 4: Endurance Prototype Chassis

Alt text: Le Mans endurance race car chassis

Placement: Section 10

Conclusion: Lightweight Chassis as the Core of Racing Excellence

From early steel frames to cutting-edge carbon fiber monocoques, lightweight racing chassis engineering has transformed motorsport. Today’s racing cars represent a perfect balance between:

- Structural strength

- Aerodynamic efficiency

- Safety innovation

- Performance optimization

Whether in Formula 1, IndyCar Series, or endurance racing, the chassis remains the foundation of competitive success.

The future promises even lighter, stronger, and smarter chassis systems — pushing motorsport to new limits of speed and safety.

If you’d like, I can next provide:

- ✅ A downloadable WordPress-ready HTML version

- ✅ Meta description + focus keyword strategy

- ✅ 100+ SEO keyword cluster list

- ✅ Image generation prompts for AI design tools

- ✅ Schema markup for rich results 🖼 Images for Your Website (Suggested Placement)

1️⃣ Hero Image – Carbon Fiber Monocoque Chassis

📍 Placement: Directly below the article title

🎯 Purpose: Visual impact + SEO engagement

Image Idea:

Close-up of a carbon fiber monocoque racing chassis in a motorsport workshop, showing weave texture and structural reinforcement points.

Alt Text (SEO Optimized):

Lightweight carbon fiber monocoque racing chassis structure

Caption Example:

Modern racing chassis use advanced carbon fiber composites for maximum strength and minimal weight.

2️⃣ Space Frame Chassis Structure

📍 Placement: After “Monocoque vs Space Frame” section

Image Idea:

Tubular steel space frame chassis with visible triangulated structure.

Alt Text:

Tubular space frame lightweight race car chassis

Caption:

Space frame chassis designs offer rigidity through triangulated tube construction.

3️⃣ Formula-Style Survival Cell

📍 Placement: After “Safety Engineering” section

Image Idea:

Driver survival cell with halo structure and reinforced side impact panels.

Alt Text:

Carbon fiber racing survival cell safety structure

Caption:

The survival cell protects drivers during high-speed impacts.

4️⃣ Torsional Rigidity Testing

📍 Placement: After “Torsional Rigidity” section

Image Idea:

Chassis mounted on a torsional test rig with load measurement equipment.

Alt Text:

Race car chassis torsional rigidity test setup

Caption:

Engineers test chassis stiffness to ensure optimal handling performance.

5️⃣ Aerodynamic Integration View

📍 Placement: After “Aerodynamics and Chassis Integration”

Image Idea:

Exploded view showing chassis integrated with diffuser and underbody tunnels.

Alt Text:

Race car chassis integrated with aerodynamic components

Caption:

Chassis design directly influences aerodynamic performance.

6️⃣ Endurance Prototype Chassis

📍 Placement: After “Endurance Racing” section

Image Idea:

Lightweight chassis of an endurance prototype car before body panels are installed.

Alt Text:

Endurance racing prototype lightweight chassis

Caption:

Endurance chassis balance weight reduction with durability.

7️⃣ Electric Racing Car Chassis Layout

📍 Placement: After “Electric & Hybrid Racing” section

Image Idea:

Chassis with integrated battery pack and cooling system layout.

Alt Text:

Electric race car chassis with battery integration

Caption:

Battery placement significantly affects weight distribution.

8️⃣ Material Comparison Graphic

📍 Placement: After “Materials Used in Lightweight Racing Chassis”

Image Idea:

Side-by-side comparison graphic: steel vs aluminum vs carbon fiber.

Alt Text:

Racing chassis material comparison steel aluminum carbon fiber

Caption:

Carbon fiber provides the highest strength-to-weight ratio.

9️⃣ Manufacturing Process – Autoclave

📍 Placement: After “Manufacturing Techniques” section

Image Idea:

Carbon fiber chassis being cured inside an autoclave chamber.

Alt Text:

Carbon fiber racing chassis autoclave curing process

Caption:

Autoclave curing ensures maximum structural strength.

🔟 Weight Distribution Diagram

📍 Placement: After “Weight Distribution & Center of Gravity”

Image Idea:

Diagram showing front-rear weight balance and center of gravity location.

Alt Text:

Race car weight distribution and center of gravity diagram

Caption:

Proper weight distribution improves cornering stability.

🎯 SEO Image Optimization Checklist

For every image:

✔ File name example: lightweight-racing-chassis-carbon-fiber.jpg

✔ Add keyword-rich alt text

✔ Use compressed WebP format

✔ Add structured data (ImageObject schema)

✔ Minimum resolution: 1200px width

✔ Use lazy loading for speed

🔗 Internal Linking Suggestions Around Images

Add contextual internal links like:

“Learn more about race car aerodynamics”

“Explore our guide on carbon fiber race cars”

“Read about motorsport safety technology”

“See our complete breakdown of race car suspension setup”

📐 Recommended Image Sizes for Website

Placement

Size

Hero Image

1920×1080

Section Images

1200×800

Infographics

1200×1200

Thumbnails

800×600

If you want, I can next create:

✅ Custom AI image prompts (ready for Midjourney/DALL·E)

✅ SEO-optimized infographic layout

✅ Pinterest vertical image design (1000×1500)

✅ Featured image banner for WordPress

✅ 5 social media promotional images

Just tell me what you need next 🚗🔥

Just tell me what you need next 🚗🔥