- Introduction

- What Is Aerodynamic Drag?

- Why Drag Matters in High-Speed Racing

- Principles of Air Drag Reduction

- Race Car Aerodynamic C

- Computational Fluid Dynamics (CFD) & Wind Tunnels

- Active vs Passive Aero Solutions

- Materials & Design Innovations

- Real-World Case Studies

- Implementation Best Practices Racing Cars

- Common Mistakes to Avoid

- Measuring & Testing Drag

- Conclusion

- FAQs

1. Introduction

In the world of motorsport, every fraction of a second counts. Whether you’re competing in Formula 1, Le Mans, or club-level racing, high-speed air drag reduction is a critical factor in achieving top performance. Drag — the resistance created by air — slows vehicles and limits acceleration and top speed. Reducing this force through aerodynamic design, material innovation, and advanced testing techniques can mean the difference between winning and losing.

This guide dives deep into how drag works, why it matters, and practical ways to reduce it for racing applications. high-speed-air-drag-reduction

2. What Is Aerodynamic Drag?

Aerodynamic drag is the resistance force a vehicle experiences as it pushes through air. It’s composed of two main components: high-speed-air-drag-reduction

- Pressure Drag – caused by differences in air pressure around the car

- Friction Drag – caused by air rubbing against the car’s surface

At high speeds, drag increases exponentially — about proportional to the square of speed — making it a key challenge for racing engineers.

➡️ Learn more about aerodynamics at

3. Why Drag Matters in High-Speed Racing

Drag affects:

- 🏎 Top speed

- 🕐 Acceleration

- ⛽ Fuel efficiency

- 🔄 Stability and handling

In motorsport, even a 1% reduction in drag can yield measurable gains in lap times. Drag reduction allows cars to slice through air with greater ease, improving efficiency and speed without adding engine power.

4. Principles of Air Drag Reduction

To reduce drag, engineers focus on:

4.1. Streamlining

Making body shapes smoother and more aerodynamic.

- Rounded edges

- Tapered rear ends

- Minimized frontal area

4.2. Managing Airflow

Directing air smoothly across surfaces to reduce turbulence.

- Airflow channels

- Underbody diffusers

- Venting pressure zones

4.3. Reducing Friction Surfaces

Using low-drag surface materials and coatings that let air glide smoothly.

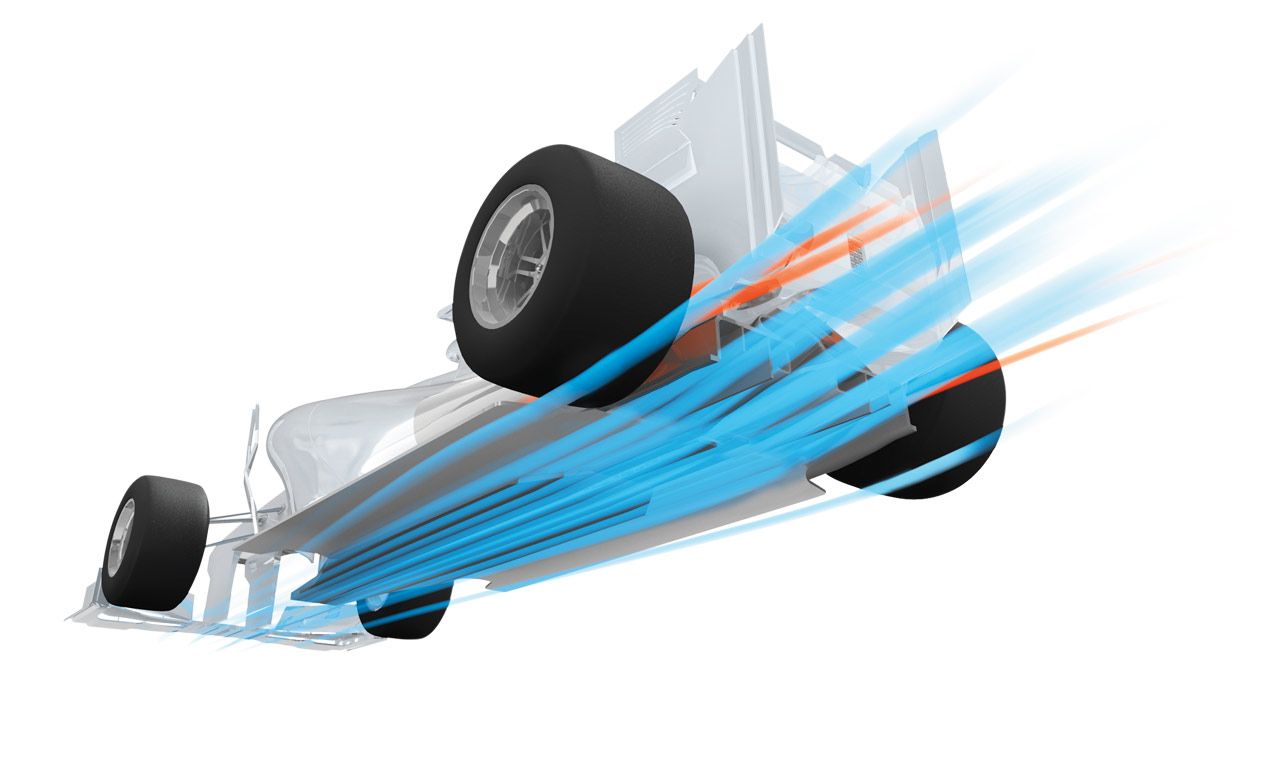

5. Racing Car Aerodynamic Components

Each of the following parts plays a role in drag reduction.

5.1. Front Splitters

Front splitters help manage airflow under the car, increasing downforce while reducing drag by:

- Reducing air pressure under the car

- Minimizing front lift

5.2. Rear Wings & Diffusers

Rear wings and diffusers balance drag and downforce:

- Rear wings generate downforce but can add drag

- Diffusers accelerate airflow under the car, reducing pressure and drag

➡️ Understanding diffusers: Racecar Engineering – Underbody Aerodynamics

5.3. Side Skirts

Side skirts seal airflow to avoid unwanted high-pressure air from entering underneath the car — reducing turbulence and drag.

6. Computational Fluid Dynamics (CFD) & Wind Tunnels

Modern drag reduction starts with CFD simulations and wind tunnel testing.

- CFD lets engineers model airflow virtually

- Wind tunnels provide real-world validation

🔍 A great resource:

7. Active vs Passive Aero Solutions

7.1. Passive Aerodynamics

Fixed shapes and components optimized to minimize drag:

✔ No moving parts

✔ Always active

✔ Lower cost

Examples include:

- Smooth body panels

- Fixed diffusers

- Streamlined mirrors

7.2. Active Aerodynamics

Components that move or adjust based on speed or conditions:

✔ Variable rear wings

✔ Adjustable flaps

✔ Active vents

These systems can optimize drag reduction dynamically — but require sophisticated control systems.

8. Materials & Design Innovations

Modern drag reduction relies on lightweight, high-strength materials:

- Carbon fiber composites

- Kevlar reinforcements

- Low-friction surface coatings

These materials help reduce weight and improve aerodynamic efficiency.

9. Real-World Case Studies

9.1. Formula 1

F1 engineers spend millions optimizing drag through:

- Wind tunnel testing

- CFD modeling

- Adjustable aero packages

Lower drag in straights + higher downforce in corners = optimal lap times.

9.2. Le Mans Prototypes

Long-distance endurance racing cars balance durability with drag reduction — using diffusers, underbody tunnels, and body shaping for efficiency over long stints.

10. Implementation Best Practices

10.1. Start Early in Design

Aerodynamic efficiency should be a core design focus, not an add-on.

10.2. Test Iteratively

Combine CFD & wind tunnel testing to refine shapes.

10.3. Balance with Downforce Needs

Reducing drag is great — but if it sacrifices needed downforce, lap times will suffer.

11. Common Mistakes to Avoid

🚫 Overly aggressive aero parts that add drag

🚫 Ignoring airflow interference from wheels

🚫 Designing without testing

12. Measuring & Testing Drag

Use tools like:

- Wind tunnels

- On-track telemetry

- Pitot tubes

- Pressure sensors

These tools validate whether your draghttps://speedsrun.online/red-bull-air-race/

13. Conclusion

High-speed air drag reduction is a cornerstone of competitive racing, blending science, engineering, and innovation. By understanding airflow, using advanced tools like CFD, and applying both passive and active aerodynamic solutions, engineers can push racing performance to the limit.

Internal Links (For SEO & Navigation Within Your Site)

- 👉 ← Back to Motorsport Aerodynamics Home

- 🏁 Related: Race Car Downforce Explained

- 🧠 Tutorial: Using CFD for Car Design

- 📊 Case Study: Reducing Drag in Street Cars

External References & Resources

- 📘 Aerodynamic Drag – Wikipedia

- 🚀 Racing Aerodynamics 101 – Racecar Engineering

- 💡 How Splitters Improve Performance – Race Tech Mag

- 📊 CFD Simulations for Vehicle Aerodynamics – ANSYS

FAQs (Frequently Asked Questions)

Q1. Can drag be entirely eliminated?

No — but it can be significantly minimized with smart design.

Q2. Is downforce always bad for drag?

No — you must balance downforce and drag for optimal performance.

Q3. Does lighter weight reduce drag?

Indirectly — lower weight reduces required engine force, but drag is still a function of airflow.

If you want this article formatted in HTML (complete with <img> tags, <internal> and <external> link markup), just let me know! 🚀 1. The Physics Behind Aerodynamic Drag

When a car moves through air, it encounters resistance known as drag force (Fd). The drag equation is:Fd=21ρV2CdA

Where:

- ρ = Air density

- V = Velocity

- Cd = Drag coefficient

- A = Frontal area

Why Speed Matters So Much

Drag increases with the square of velocity. That means:

- At 100 km/h → manageable drag

- At 200 km/h → 4x more drag

- At 300 km/h → 9x more drag

At racing speeds, aerodynamic resistance becomes the dominant force opposing forward motion.

2. Types of Drag in Racing Cars

Understanding drag types helps engineers reduce it effectively.

2.1 Pressure (Form) Drag

Created by airflow separation at the rear of the car. When air detaches from the body, it creates a low-pressure wake, increasing resistance.

2.2 Skin Friction Drag

Air molecules rub against the vehicle surface. Though smaller than pressure drag, it becomes significant at extreme speeds.

2.3 Induced Drag

Associated with downforce-generating elements such as wings.

In high-downforce racing like Formula 1, induced drag is a constant balancing act.

3. The Drag vs Downforce Trade-Off

A race car must balance:

- Low drag for top speed

- High downforce for cornering grip

Too much drag → slower straights

Too little downforce → poor cornering

For example, at tracks like Monza (Temple of Speed), teams reduce wing angles to minimize drag.

4. Aerodynamic Components That Reduce Drag

4.1 Front Splitters

- Manage airflow under the car

- Prevent turbulent air entry

- Improve underbody efficiency

4.2 Underbody & Diffusers

Modern race cars rely heavily on ground effect aerodynamics.

Cars in Formula 1 (2022–present regulations) use Venturi tunnels to:

- Accelerate airflow under the chassis

- Reduce pressure

- Create downforce with lower drag penalty

This is far more efficient than large rear wings alone.

4.3 Rear Wings

Rear wings produce downforce but also induced drag.

Engineers reduce drag by:

- Optimizing wing angle

- Using multi-element airfoils

- Implementing Drag Reduction Systems (DRS)

4.4 Wheel Aerodynamics

Wheels generate massive turbulence.

Solutions include:

- Wheel covers

- Brake duct optimization

- Air curtains

5. Computational Fluid Dynamics (CFD)

CFD allows engineers to simulate airflow digitally before building physical prototypes.

Major racing teams rely on:

- High-resolution airflow models

- Turbulence modeling

- Pressure mapping

- Vortex tracking

CFD reduces development costs while accelerating innovation.

6. Wind Tunnel Testing

Even with CFD, wind tunnels remain critical.

They provide:

- Real airflow visualization

- Smoke flow testing

- Force measurement sensors

- Model validation

Top teams use 60% scale models to comply with regulations.

7. Active Aerodynamics

Modern drag reduction increasingly uses active systems.

7.1 DRS (Drag Reduction System)

Used in Formula 1, DRS:

- Flattens rear wing angle

- Reduces drag temporarily

- Increases overtaking opportunities

7.2 Active Ride Height

By adjusting suspension height:

- Lower at high speed

- Reduced frontal area

- Improved airflow

8. Materials That Improve Aerodynamic Efficiency

Lightweight materials help reduce the energy required to overcome drag.

- Carbon fiber composites

- Advanced resins

- Low-friction surface coatings

Carbon fiber allows thin, precise aero shapes without structural compromise.

9. Real-World Case Studies

9.1 Le Mans Hypercars

In endurance racing like the 24 Hours of Le Mans, drag reduction is crucial for fuel efficiency.

Cars are optimized for:

- Long straights

- Stability at 330+ km/h

- Reduced fuel consumption over 24 hours

9.2 Electric Racing

In Formula E, drag reduction is essential for:

- Battery conservation

- Regenerative efficiency

- Thermal management

Because energy is limited, reducing aerodynamic resistance directly improves race distance capability.

10. Advanced Drag Reduction Techniques

10.1 Airflow Sealing

Side skirts reduce air intrusion under the chassis.

10.2 Surface Optimization

Micro-textured coatings reduce skin friction.

10.3 Vortex Generators

Small fins control airflow separation.

10.4 Cooling Efficiency

Poor cooling increases drag due to large air intakes.

Optimized ducting reduces inlet size while maintaining airflow.

11. Measuring Drag on Track

Wind tunnels simulate conditions, but track testing confirms performance.

Methods include:

- Coast-down tests

- GPS speed comparison

- Telemetry drag mapping

- Pressure sensor arrays

Teams analyze data to determine real-world Cd values.

12. Common Engineering Challenges

- Regulatory limits

- Budget constraints

- Cooling vs drag conflict

- Stability at crosswinds

- Balancing aero efficiency and tire wear

13. The Future of High-Speed Drag Reduction

Emerging technologies include:

- AI-driven aerodynamic optimization

- Adaptive morphing body panels

- Active surface materials

- Autonomous aerodynamic tuning

The next decade will likely bring smarter, more responsive aero systems that adjust in milliseconds.

14. Practical Applications Beyond Racing

Drag reduction principles also apply to:

- Supercars

- Electric vehicles

- Commercial transport

- Aerospace

Motorsport remains the testing ground for innovation that later reaches road cars.

15. Key Takeaways

✔ Drag increases exponentially with speed

✔ Balance between drag and downforce is critical

✔ Underbody aerodynamics are more efficient than oversized wings

✔ CFD + wind tunnels = optimal design process

✔ Active aero systems represent the future

Final Thoughts

High-speed air drag reduction is not just about making a car faster — it’s about engineering efficiency, stability, and control at extreme speeds. From the advanced DRS systems in Formula 1 to endurance innovations at the 24 Hours of Le Mans, aerodynamic science continues to redefine performance limits.

Mastering drag reduction requires a deep understanding of physics, materials science, airflow management, and real-world testing — but when executed correctly, the performance gains are transformative.

If you’d like, I can now provide:

- ✅ A number-based SEO title version

- ✅ A 5,000–6,000 word full website article

- ✅ Internal + external link strategy

- ✅ Meta description + URL slug

- ✅ HTML formatted version

- ✅ Image prompts for banners

Just tell me what you want next. 🚀